How we make it greener Earthwool® 1000° Pipe Insulation ASJ+

Utilize recycled content

By leveraging recycled content, we reduce the energy required to form glass fibers.

Pursue sequestration potential

Manson and Knauf's bio-based ECOSE Technology is derived from corn. While we don’t grow the corn used in our products, the use of corn has a significant carbon sequestration impact on our processes. For instance, the use of corn actually offsets the carbon impact of some of the ancillary facers used on our products.

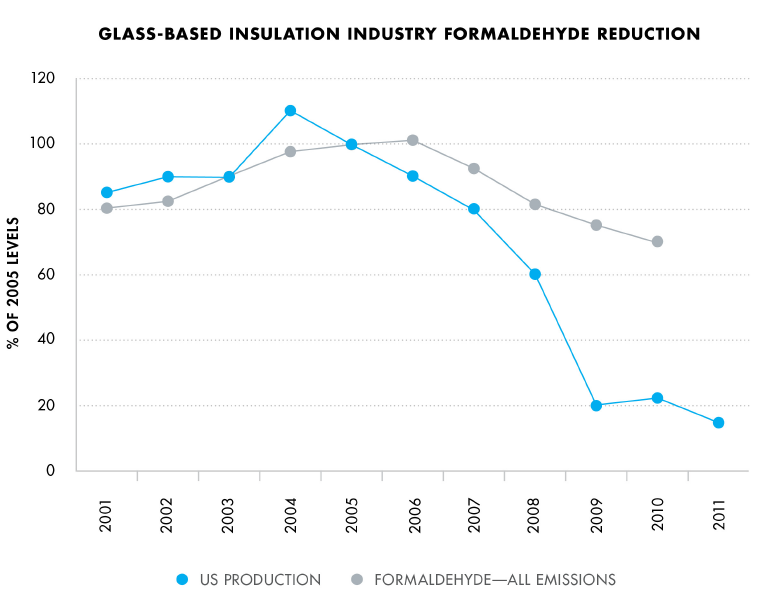

Lead green chemistry efforts

Following the launch of our ECOSE Technology in 2009, we had transformed most of our products and processes to this new technology. Using our bio-based ECOSE Technology has removed phenol and formaldehyde from our stack emissions. By 2012, the entire industry had followed our lead. This initiative not only established Manson and Knauf Insulation in a leadership position, but it had a transformative impact on our industry in general.

Reduce scrap generation and energy consumption

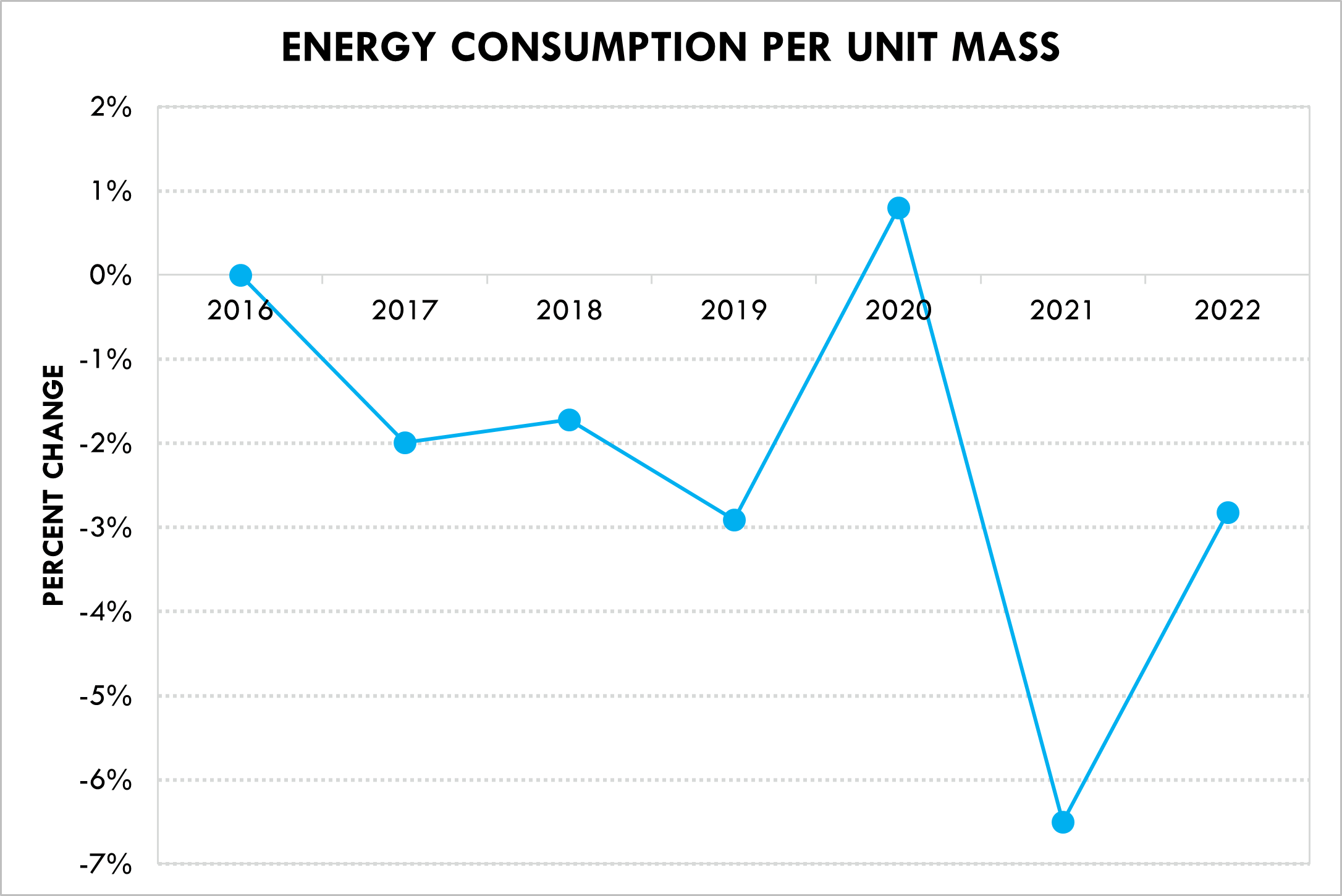

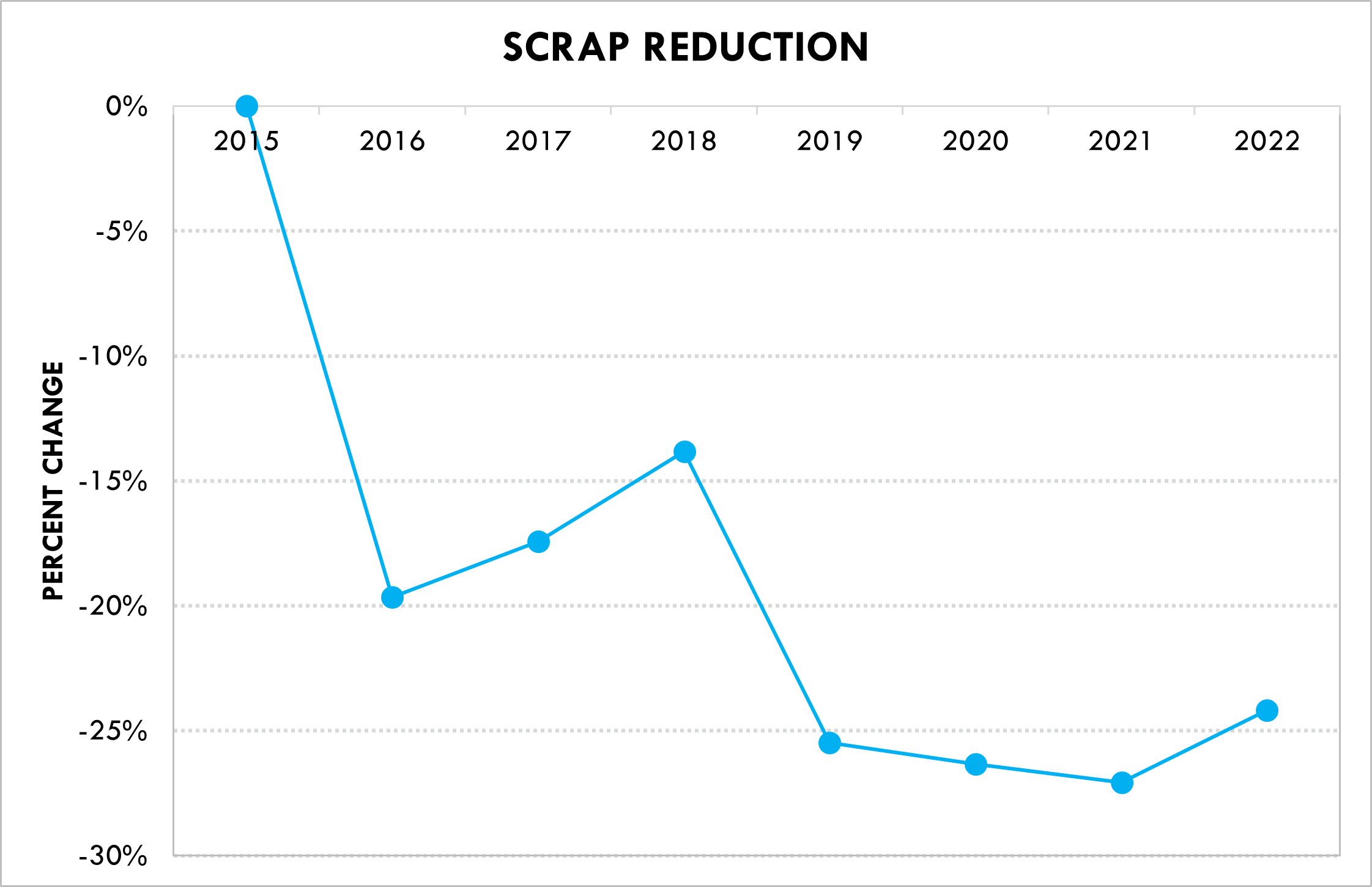

Continuous improvement is the methodology we utilize to engage the entire Knauf team in our manufacturing excellence and sustainment journey. Knauf Insulation, comprised of Knauf Insulation North America (KINA) and Knauf Insulation Europe Middle East, Asia, Asia Pacific (KI EMEA & APAC), share an overall global certification for ISO 45001 Health & Safety, ISO 14001 Environmental, ISO 50001 Energy, and ISO 9001 Quality through a third-party Certification Body.

KINA’s Continuous Improvement Program, with all its tools and systems associated with it, provide a formal process where we are constantly monitoring our manufacturing and sustainability Key Performance Indicators (KPIs) with an eye towards improvement. This Continuous Improvement centric management system has proven to be effective in improving our sustainability by reducing scrap generation and energy consumption.

Green manufacturing processes

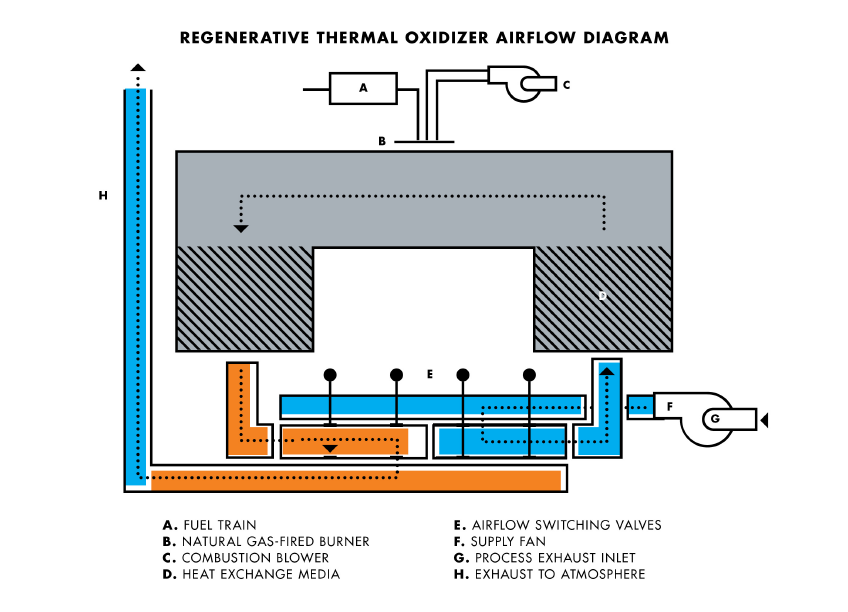

1. Regenerative thermal oxidizers Manson and Knauf Insulation use regenerative thermal oxidizers (RTO) to capture and recycle much of the energy we used to cure our products. RTO is equipment used for the treatment of exhaust air. Our ovens exhaust into a ceramic heat exchange media to capture and reuse the heat in the exhausted air. Therefore, the amount of energy required to cure our product is reduced substantially.

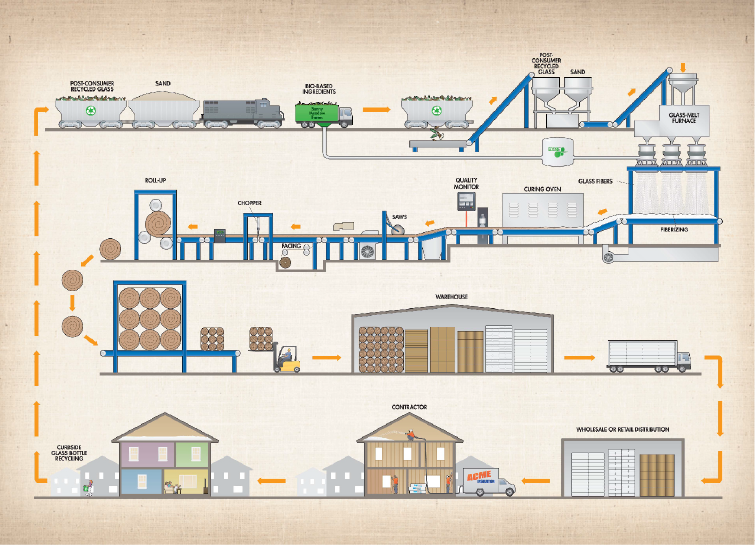

2. Recycling As you can see below, everything we do starts with recycling. Our plant uses as much as 80% recycled content. While our only option is to landfill our products at end of life, that doesn’t stop us from encouraging consumers to recycle other products, particularly glass bottles.

Leverage compression packaging

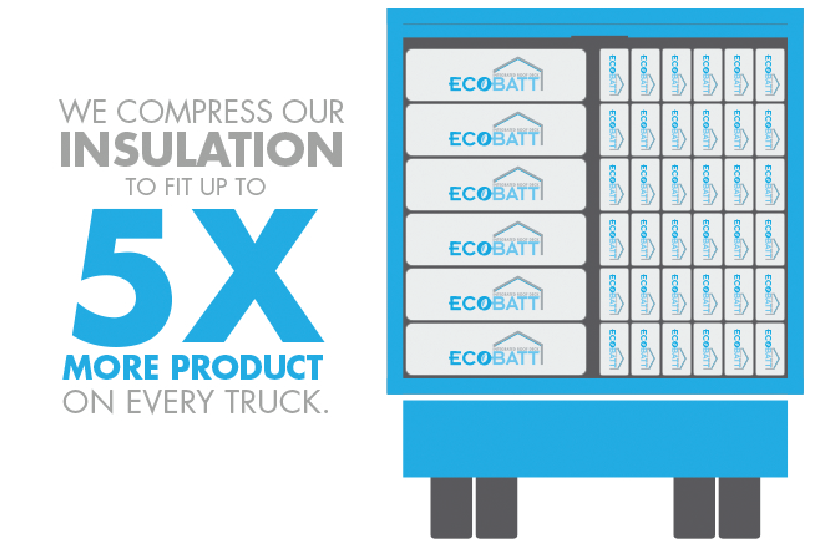

Glass is a high modulus material, which helps to facilitate compression packaging. We compress our insulation to fit up to five times more product on every truck. This compression means:

- More material can fit on one truck when compared to other insulation materials

- Fewer packages on a job

- Fewer deliveries needed

Be confident in glass fiber's safety

In the past, a label regarding the carcinogenic potential of insulation made from glass fibers was required on all packaging. Following forty years of research, fiberglass has been exonerated entirely. Knauf Insulation fiberglass is comprised of fibers that are biosoluble, meaning that the fibers dissolve in the body in a short period of time and exit the body with normal bodily functions. The scrutiny fiberglass has undergone is now seen as proof of its safety.

Meet and exceed green standards

GREENGUARD certified On the forefront of indoor air quality,

Knauf Insulation was the first GREENGUARD certified product in

2002. This achievement led us to understand the impact our

formaldehyde-free products could have on the indoor

environment. The formaldehyde-free claim is third party

validated by UL Environment.

EUCEB tested Glass fiber is perhaps the most widely studied building material available today. All of our processes and formulations are voluntarily third-party audited for compliance with the health and safety exoneration criteria for glass and rock based fiber through the European Certification Board for Mineral Wool Products (EUCEB) exoneration process. This guarantees the formulations are biosoluble and pose no health concerns. Having 35 years of research behind its safety, perhaps no other building material has been as thoroughly evaluated as fiberglass products. We believe a safe product is one that has been thoroughly evaluated.

Green building rating systems

Our products offer a vast array of potential credits for major green building rating systems, including: WELL, LEED v4, International Green Construction Code, Green Guide for Heath Care, NAHB Green Building Standard and more.

Visit the green building rating systems page to see all the credits you can earn using Manson and Knauf Insulation products

Promote Recycling

By taking a comprehensive approach of the benefits of recycling, Manson and Knauf Insulation advocates and promotes local recycling initiatives as well as actively participates in state and local government policy development. In addition, as a member of the North American Insulation Manufacturers Association (NAIMA) and Glass Recycling Coalition (GRC), we encourage regulatory and legislative initiatives that focus on glass recycling infrastructure deployment to increase the availability of post-consumer recycled glass.

SM Transparency Report (EPD)

SM Transparency Report (EPD)