LCA & material health results & interpretation Aquia® Dual-Max® Toilet MS654114MF & CST412MF

Scope and summary

- Cradle to gate

- Cradle to gate with options

- Cradle to grave

Functional unit

One toilet in a U.S. household that functions for 10 years. The period of 10 years is modeled as the period of application based on the average economical lifespan for residential applications. The technical lifespan is longer. The economical lifespan of commercial applications can be longer or lower due to aesthetic replacements or more intense use. The implication is that the LCA model assumes that the application ends at year 10 and that the materials will be treated in an end-of-life scenario.

Reference service life: 10 years

Default use phase scenario

10 years of service in a U.S. household with 1.133 gallon/use and 5.1 flushes/day and 2.6 people resulting in 54,852 gallons

What’s causing the greatest impacts

All life cycle stages

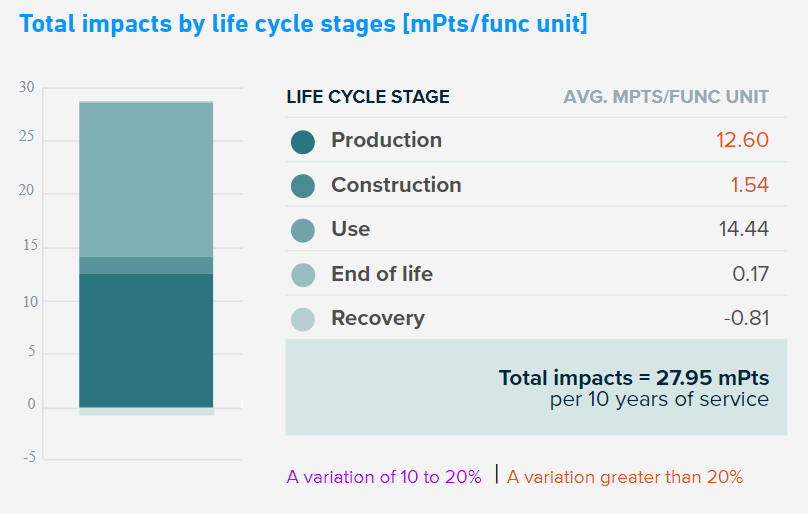

The use stage and the production stage are equally important and dominate the results for all impact categories. The impact of the use stage is mostly due to the embedded energy arising from acquisition, treatment and distribution of the water used during the operation of the product (26-62%). The production stage itself is very relevant as it shows major contributions throughout. It has the most significant contributions to ozone depletion (emissions due to the natural gas, hard coal and crude oil exploration and transportation), fossil fuel depletion (mostly defined by the natural gas used at the kiln, the use of fossil fuel based thermal power plants and the production of polypropylene) and ecotoxicity (mainly caused by stainless steel parts’ production, electricity production and the disposal of slags). The contributions covered under the construction/installation stage are mostly associated with the product delivery to the market and the disposal of packaging materials, mainly corrugated cardboard. The recovery stage includes recycling processes and benefits by preventing the need to produce primary materials. Recycling is a relevant factor for some of the impact categories, offsetting a portion of the impacts caused by production. Additionally, the delivery of the product to the construction/installation site as well as the processes for dismantling the product and final waste treatment during the end of life stage are slightly relevant in the carcinogenics, non-carcinogenics and ecotoxicity impact categories.

Production stage

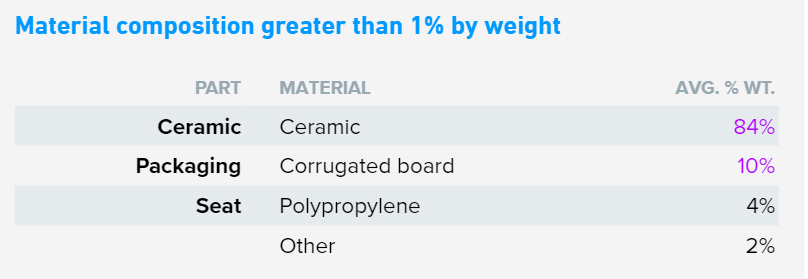

The ceramic parts dominate the material contribution except for carcinogenics. The stainless steel parts also have major contributions to the carcinogenics impact category. Additionally, the corrugated boards have a significant contribution to eutrophication. The remaining parts and processes contribute between 7% and 16% of the overall impacts in the rest of the categories.

Sensitivity analysis

Deviations are throughout, mainly because Aquia CST412MF contains more ceramic (10-20% deviation) and thus also requires more packaging material than Aquia MS654114MF (10-20% deviation). Another reason is the difference in transportation of the product to the market, as Aquia CST412MF is mainly produced outside the US while Aquia MS654114MF is produced in the US. Both products use the same amount of water and so there is no deviation in the use stage.

Multi-product weighted average

Results represent the weighted average using production volumes for the products covered. Variations of specific products for differences of 10-20% against the average are indicated in purple ; differences greater than 20% are indicated in red. A difference greater than 10% is considered significant.

TOTO PeoplePlanetWater™ programs improving environmental performance

- Dual-Max®, E-Max®, Tornado Flush™, 1G®, and EcoPower® reduce water consumption in the use phase

- Energy efficiency programs optimize the firing process

- 50% electricity from renewable energy

- 100% of post-industrial ceramic waste is recycled

LCA results

| Life cycle stage | Production | Construction | Use | End of Life | Recovery |

|

Information modules: Included | Stages D2 and D3 are being excluded. Operational energy use is irrelevant to the life cycle of the modeled product. Reuse and energy recovery are not modeled for toilets and/or urinals. |

A1 Raw Materials | A4 Transporation/ Delivery | B1 Use | C1 Deconstruction/ Demolition | D1 Recycling |

| A2 Transportation | A5 Construction/ Installation | B2 Maintenance | C2 Transportation | D2 Recovery | |

| A3 Manufacturing | B3 Repair | C3 Waste processing | D3 Reuse | ||

| B4 Replacement | C4 Disposal | ||||

| B5 Refurbishment | |||||

| B6 Operational energy use | |||||

| B7 Operational water use | |||||

|

|

|

|

|

SM Single Score

Learn about SM Single Score results| Impacts per 10 years of service | 12.60 mPts | 1.54 mPts | 14.44 mPts | 0.17 mPts | -0.81 mPts |

| Materials or processes contributing >20% to total impacts in each life cycle stage | Ceramic parts production as well as well zinc and brass parts together with zinc turning process. | Transportation of the product to installation site or consumer and disposal of packaging. | Volume of water use during the operation of the product and the embedded energy use (such as electricity) in the water used. | Transport to waste processing, waste processing and disposal of material flows transported to a landfill. | Plastic and metal components' recycling processes. |

TRACI

- A variation of 10 to 20%

- |

- A variation greater than 20%

| Life cycle stage | Production | Construction | Use | End of Life | Recovery |

Ecological damage

Human health damage

Additional environmental information

| Impact category | Unit | |||||

| Fossil fuel depletion | MJ, LHV Mega Joule, lower heating value Fossil fuel depletion is the surplus energy to extract minerals and fossil fuels. |

3.40E+02 | 2.61E+01 | 1.26E+02 | 3.07E+00 | -6.03E+00 |

References

LCA Background Report

TOTO Sanitary Ceramic Products LCA Background Report (public version), TOTO 2014

SM Transparency Report Framework

Part A: LCA Calculation Rules and Background Report Requirements (Draft V2) (based on ISO14040-44, ISO14025 and EN15804)

Part B: Product Group Definition – Residential Toilets

"Transparency Reports™ / environmental product declarations enable purchasers and users to compare the potential environmental performance of products on a life cycle basis. They are designed to present information transparently to make the limitations of comparability more understandable. TRs/EPDs of products that conform to the same PCR and include the same life cycle stages, but are made by different manufacturers, may not sufficiently align to support direct comparisons. They therefore, cannot be used as comparative assertions unless the conditions defined in ISO 14025 Section 6.7.2. ‘Requirements for Comparability’ are satisfied." EPDs from different programs (using different PCR) may not be comparable. TRs/EPDs cannot be compared if they do not have the same functional unit, reference service life, and building service life.

SM Transparency Report (EPD)

SM Transparency Report (EPD)