LCA results & interpretation Natural Stone Flooring and Paving

Scope and summary

- Cradle to gate

- Cradle to gate with options

- Cradle to grave

Product description

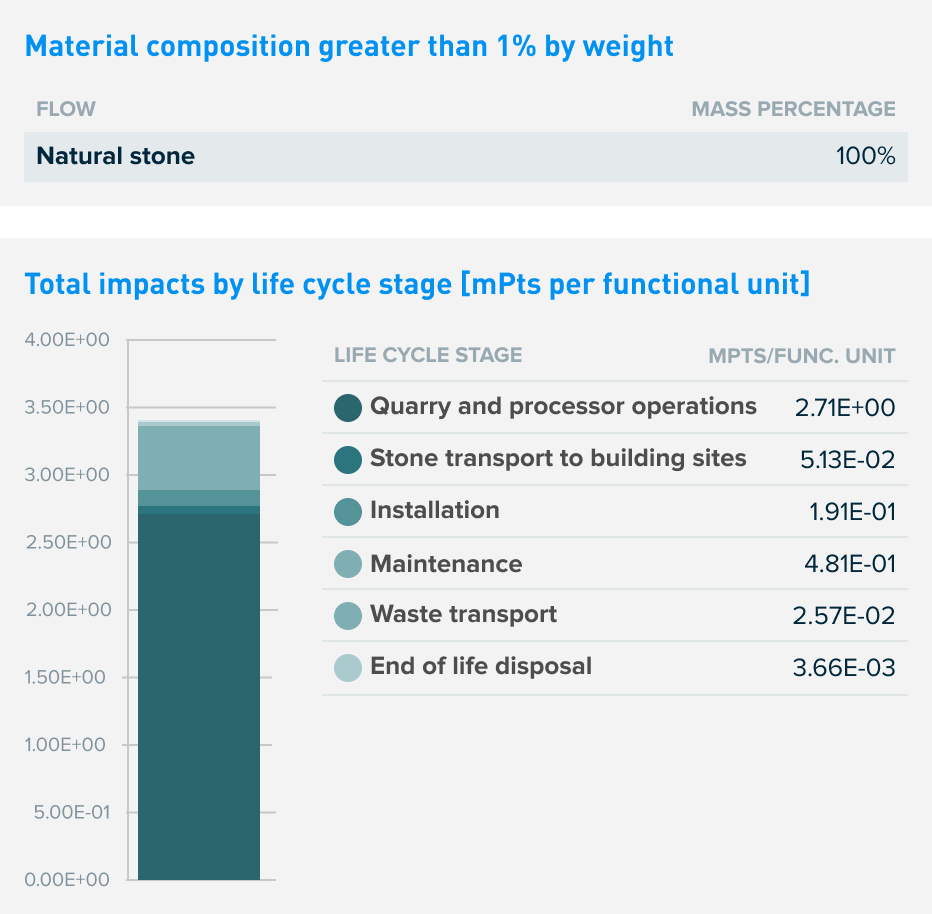

Stone flooring can be applied as interior flooring, exterior flooring, landscaping, and terracing. It tends to be durable and easy to maintain, with an elegant outlook. Natural stone makes up 100% of the total mass and the different stone types included in this study are granite, marble, quartzite, limestone, and sandstone. It is used in commercial, residential, and public sector buildings.

This transparency report represents both interior flooring with thickness ranging from 0.3125 inch to 1 inch and exterior paving with thickness ranging from 1 to 2 inch.

Functional unit

The functional unit is one square meter of floor covering. The natural stone flooring product system is an industry-average product, i.e., the product profile represents the weighted average of NSI’s natural stone flooring based on NSI’s industry-average quarrying for all stone types and also includes the industry-average production of flooring of all stone types. The product system in this study also includes the ancillary materials used in the installation of the product – mortar, grout, and acrylate. Materials needed to meet functional unit are:

Natural stone - 24.32 kg per m2

Mortar - 4.07 kg per m2

Grout - 0.21 kg per m2

Acrylate - 0.04 kg per m2

Water - 0.4 liter per m2

Manufacturing data

The data for all stone products were collected from NSI members covering a period of two years: January 2019 to December 2020. Data for quarry operations were collected from twelve NSI quarry members covering 36 quarries across North America. The participant quarries in this study are Coldspring, Delgado Stone Distributors, Freshwater Stone, Independent Limestone Company, Polycor, Quality Stone Corporation, Royal Bedrock Inc., Russell Stone Products, Stony Creek Quarry, Vermont Quarries Corporation, and Vetter Stone Company.

After the stone is extracted from the quarry, it goes to a processing facility. Stone processor operations data were collected from six NSI member processors covering 17 facilities across North America. The participant processors in this study producing flooring are Delgado Stone Distributors, Polycor, Russell Stone Products, Vetter Stone Company, and Continental Cut Stone. NSI resources and other literature data were used to develop estimates or assumptions for other upstream or downstream activities where necessary.

Industry-wide results calculation methodology

Based on data provided by the participating natural stone processors, granite and limestone represented much of natural stone flooring at 72.71% and 26.88%, respectively. Marble flooring covered 0.15% of the market share, while the rest (0.27%) was from other natural stones (including quartzite and sandstone).

For quarry data, an average inventory per kg of stone quarried for each stone category (granite, limestone, marble, and other natural stone) was developed, and later a weighted inventory per kg of stone quarried was generated using the quarry production share of each stone type among the participant quarries. After that, the inventory per kg of stone quarrying specific to stone flooring was developed using the market distribution of natural stone flooring by stone type as collected from participant stone processing facilities (72.71% granite, 26.88% limestone, 0.15% marble, and 0.27% other natural stone).

Similarly, the inventory for one square meter of processed stone flooring was developed. An average inventory per square meter of stone processed for each stone category (granite, limestone, marble, and other natural stone) was developed, and later a weighted inventory per square meter of stone processed was generated using the production share of each stone type using the stone processing share of each stone type among the participant processors. After that, the inventory per square meter of stone processing specific to flooring was developed using the market distribution of natural stone flooring (72.71% granite, 26.88% limestone, 0.15% marble, and 0.27% other natural stone). The processing inventory data is based on square meter of stone processed, which sufficiently represents both interior flooring and exterior paving products with varied thicknesses.

Data quality

Primary data was collected for a time period of two years, which represents typical operations of quarry and processors across North America. Inventory data is considered to have a good precision and provide a representative depiction of the industry average. Data is also considered to be complete as no know flows are deliberately excluded from this analysis other than those defined to be outside of the system boundary. Proxy and generic datasets have been used for some materials and processes, but are considered to be sufficiently representative.

What’s causing the greatest impacts

All life cycle stages

For the natural stone flooring product, the cradle-to-gate stage (A1-A3) dominates the results for all impact categories. This study assessed a multitude of inventory and environmental indicators. In addition to the six major impact categories (global warming potential, ozone depletion, acidification, smog, eutrophication, and fossil fuel depletion), additional impact categories have also been included. These six impact categories are globally deemed mature enough to be included in Type III environmental declarations. Other categories are being developed and defined, and LCA should continue making advances in their development. However, the EPD users shall not use additional measures for comparative purposes. LCIA results are relative expressions and do not predict impacts on category endpoints, the exceeding of thresholds, safety margins or risks.

Overall results are consistent with expectations for stone flooring's life cycles, with most of the impacts being generated during cradle-to-gate stages, as flooring is not associated with energy consumption during its use stage.

The primary finding, across the environmental indicators, was that cradle-to-gate stage (A1-A3) dominates the impacts due to the energy consumed at the quarries and processing plants. The processor operations (A3) stage is the highest contributor to most of the impact categories, followed by the maintenance stage (B2) and quarry operations (A1). The cradle-to gate-stage (A1-A3) contributes to ~60% of the total impacts in all impact categories except for ozone depletion and eutrophication. The transportation of stone from quarries to processing plants, transportation of flooring from processing plants to the installation sites, and use of mortar during installation also generate significant impacts in the overall life cycle impacts of stone flooring.

Quarry operations and transport to processors

Impacts generated at quarries (A1) are mainly due to the use of grid electricity and fuels in the quarries. Other material inputs generate little impact in comparison to the electricity and fuel consumed. The transportation of stone from quarries to processing plants also generates significant impacts in numerous impact categories.

Processor operations and transport to building sites

Manufacturing operations at processing plants make up the greatest share of all impact categories except for ozone depletion. Energy consumed at processors (both electricity and fuels) is responsible for the majority of impacts, while other material inputs have an insignificant contribution. The transportation of stone flooring manufactured in processor plants to the building sites also makes a significant impact on the overall life cycle impacts of natural stone flooring.

Other life cycle stages

Resealing of the non-granite stone flooring every five years and use of mortar during installation also generate significant impacts to the overall life cycle impacts of stone flooring. Under normal operating conditions, stone flooring requires monthly cleaning. Due to the nature of natural stone, it is anticipated that the stone flooring products will last for the lifetime of the building. The reference service life (RSL) thus meets an ESL of 75 years, and flooring will need no replacements during its service life. End-of-life stages have lower contributions on the total life cycle impacts.

Variation analysis

A variation analysis was performed to study the environmental impacts variation between natural stone flooring from different stone types. Results were generated for both quarry operations and processor operations specific to various stone types based on the production share of different quarries and processors for each stone type. One of the major parameters that influences the results is the amount of stone that needs to be quarried to produce 1 m2 of stone flooring.

The variation between weighted average, minimum, and maximum LCIA results is greater than 20% for all impact categories. This is due to varying quarry and processor operations used by different quarries and processors.

Sensitivity analysis

Based on NSI's expert judgement, it was assumed that energy consumed for processing of a square meter of stone flooring matches the average energy consumed for processing of different stone products. A sensitivity analysis was performed to check the robustness of the results when the energy consumed during processing is varied by +/-20% from the estimate used in this study. The resulting variation in the total life cycle impacts is about 10%, implying that the system is not sensitive to this assumed value.

Another parameter that affects the overall life cycle impacts is the thickness of stone flooring. The thickness of stone flooring studied in this study varied from 0.3125 inch to 2 inch. Results have been presented for a typical interior thickness of 0.5 inch but as the functional mass of varies with the thickness, the impacts also vary. A sensitivity analysis has thus been conducted for various thicknesses of stone flooring used for different flooring applications. For the thickness of 1.25 inch and larger, the variation in overall life cycle impacts is greater than 20%, implying that the system is sensitive to thickness value.

How we're making it greener

The natural stone industry is committed to making sure our inherently eco-friendly building material is produced efficiently and responsibly. Though the Natural Stone Sustainability Standard we have defined metrics for responsible production in the following categories:

- Energy

- Water

- Chemicals

- Land reclamation & adaptive reuse

- Site management

- Transportation

- Social governance

- Human health & safety

- Excess process materials

- Solid waste

- Innovation

Companies have the opportunity to third-party verify compliance with these metrics. As the industry’s leader in education, the Natural Stone Institute is also striving to build awareness about best practices for sustainability among all quarriers and fabricators globally.

LCA results

| Life cycle stage | A1-A3 Production (Quarry and Processor operations) |

A4 Stone transport to building sites |

A5 Installation |

B1-B7 Use |

C1-C2 Deconstruction and Waste transport |

C3-C4 Waste processing and End-of-life disposal |

|

Information modules: Included (X) | Excluded* (MND) |

A1 Quarry operations | A4 Transport to building sites | A5 Installation | B1 Use | C1 Deconstruction | C3 Waste Processing |

| A2 Transport to processors | B2 Maintenance | C2 Waste transport | C4 End of life disposal | |||

| A3 Processor operations | B3 Repair | |||||

| B4 Replacement | ||||||

| B5 Refurbishment | ||||||

| B6 Operational energy use | ||||||

| B6 Operational water use | ||||||

|

|

|

|

|

|

SM Single Score

Learn about SM Single Score results| Impacts of 1 square meter of floor covering | 2.71E+00 mPts | 5.13E-02 mPts | 1.19E-01 mPts | 4.81E-01 mPts | 2.57E-02 mPts | 3.66E-03 mPts |

| Materials or processes contributing >20% to total impacts in each life cycle stage | Energy consumed during stone quarrying and processing (electricity and fuels). | Truck transportation used to transport product to building site. | Use of ancillary materials (mainly mortar) for installation. | Materials consumed for maintenance. | Waste transport to the landfill centers. | Landfilling after the end of life. |

TRACI v2.1 results per functional unit

| Life cycle stage | A1-A3 Production (Quarry and Processor operations) |

A4 Stone transport to building sites |

A5 Installation |

B2 Maintenance |

C2 Waste transport |

C4 End-of-life disposal |

Ecological damage

Human health damage

Additional environmental information

| Impact category | Unit | ||||||

| Fossil fuel depletion | MJ surplus Mega Joule, lower heating value Fossil fuel depletion is the surplus energy to extract minerals and fossil fuels. |

2.77E+01 | 2.48E+00 | 2.44E+00 | 1.06E+01 | 1.24E+00 | 1.44E-01 |

| Ecotoxicity | CTUe Comparative Toxic Units of Ecotoxicity Ecotoxicity causes negative impacts to ecological receptors and, indirectly, to human receptors through the impacts to the ecosystem. |

2.38E+01 | 6.63E-01 | 5.82E-01 | 7.36E+00 | 3.32E-01 | 6.46E-03 |

References

LCA Background Report

NSI Natural Stone Flooring LCA Background Report (public version), NSI 2022. SimaPro Analyst 9.4, ecoinvent 3.4 database.

ISO 21930:2017 serves as the core PCR along with EN 15804 and SM Part A.

SM PCR Part A: Life Cycle Assessment Calculation Rules and Report Requirements, v2018

March, 2018. Document created by Joep Meijer, Naji Kasem, and Kim Lewis and is managed and maintained by the Sustainable Minds Technical Advisory Board (TAB) as outlined in ISO 14025:2006.

SM PCR Part B: Product group definition for Interior and exterior stone flooring, 2022

April, 2022. Part B review conducted by the Sustainable Minds TAB, [email protected]

ISO 14025, “Sustainability in buildings and civil engineering works -- Core rules for environmental product declarations of construction products and services”

Download PDF SM Transparency Report, which includes the additional EPD content required by the SM Part B.

SM Transparency Reports (TR) are ISO 14025 Type III environmental declarations (EPD) that enable purchasers and users to compare the potential environmental performance of products on a life cycle basis. They are designed to present information transparently to make the limitations of comparability more understandable. A limitation to this study is that not all manufacturers in North America participated. TRs/EPDs of products that conform to the same PCR and include the same life cycle stages, but are made by different manufacturers, may not sufficiently align to support direct comparisons. They therefore, cannot be used as comparative assertions unless the conditions defined in ISO 14025 Section 6.7.2. ‘Requirements for Comparability’ are satisfied. Comparison of the environmental performance of building envelope thermal insulation using EPD information shall be based on the product’s use and impacts at the building level, and therefore EPDs may not be used for comparability purposes when not considering the building energy use phase as instructed under the PCR. Full conformance with the PCR for stone flooring allows EPD comparability only when all stages of a life cycle have been considered, when they comply with all referenced standards, use the same sub-category PCR, and use equivalent scenarios with respect to construction works. However, variations and deviations are possible. Example of variations: Different LCA software and background LCI data sets may lead to different results upstream or downstream of the life cycle stages declared.

SM Transparency Report (EPD)

SM Transparency Report (EPD)