LCA & material health results & interpretation SonaKrete

Scope and summary

- Cradle to gate

- Cradle to gate with options

- Cradle to grave

Application

SonaKrete is a spray applied acoustical texture designed for a wide range of project types. SonaKrete provides an attractive, high performance solution to acoustical and lighting design objectives in both new construction and renovation projects.

Functional unit

Reference service life: 75 years. One square meter of installed insulation material, packaging included, with a thickness that gives an average thermal resistance of RSI=1m2·K/W over a period of 75 years.

Reference flow: 4.252 kg of product

Thickness: 0.0483 m

Manufacturing data

Reporting period: January 2018-December 2018

Location: Houston, TX

Default installation, packaging, and disposal scenarios

At the installation site, insulation products are unpackaged and installed with a blowing machine. The insulation blower is used to spray on the fiber and adhesive. The potential impact of the blower is included in this study. Plastic packaging waste is disposed (100% to landfill), and no maintenance or replacement is required to achieve the product's life span. 12,329 kWh of electricity and 82,118 kg of water are used annually for installation. After removal, the insulation is assumed to be landfilled.

Data used for this project represents a mix of primary data collected from ICC on the production of the insulation products (gate-to-gate) and background data from SimaPro databases. Overall, the quality of the data used in this study is considered to be high and representative of the described systems. Data on processing materials and manufacturing the insulation products were collected in a consistent manner and level of detail to ensure high quality data. All submitted data were checked for quality multiple times on the plausibility of inputs and outputs. All questions regarding data were resolved with ICC. Data were collected at ICC’s Houston, TX facility.

No substances required to be reported as hazardous are associated with the production of this product. This is a product free of Red List ingredients.

What’s causing the greatest impacts

All life cycle stages

The raw material acquisition and manufacturing stages (A1-A3) and the construction and installation stage (A5) dominate the results for all impact categories except for non-carcinogenics and ecotoxicity where the transportation stage dominates. The raw material acquisition and manufacturing stages (A1-A3) dominate carcinogenics, respiratory effects, smog, and fossil fuel depletion. The construction and installation stage dominates acidification, eutrophication, global warming, and ozone depletion.

Data used for this project represents a mix of primary data collected from ICC on the production of the insulation products (gate-to-gate) and background data from SimaPro databases. Overall, the quality of the data used in this study is considered to be high and representative of the described systems. Data on processing materials and manufacturing the insulation products were collected in a consistent manner and level of detail to ensure high quality data. All submitted data were checked for quality multiple times on the plausibility of inputs and outputs. All questions regarding data were resolved with ICC. Data were collected at ICC’s Houston, TX facility.

No substances required to be reported as hazardous are associated with the production of this product. This is a product free of Red List ingredients.

Raw materials acquisition and manufacturing stage and construction and installation stage

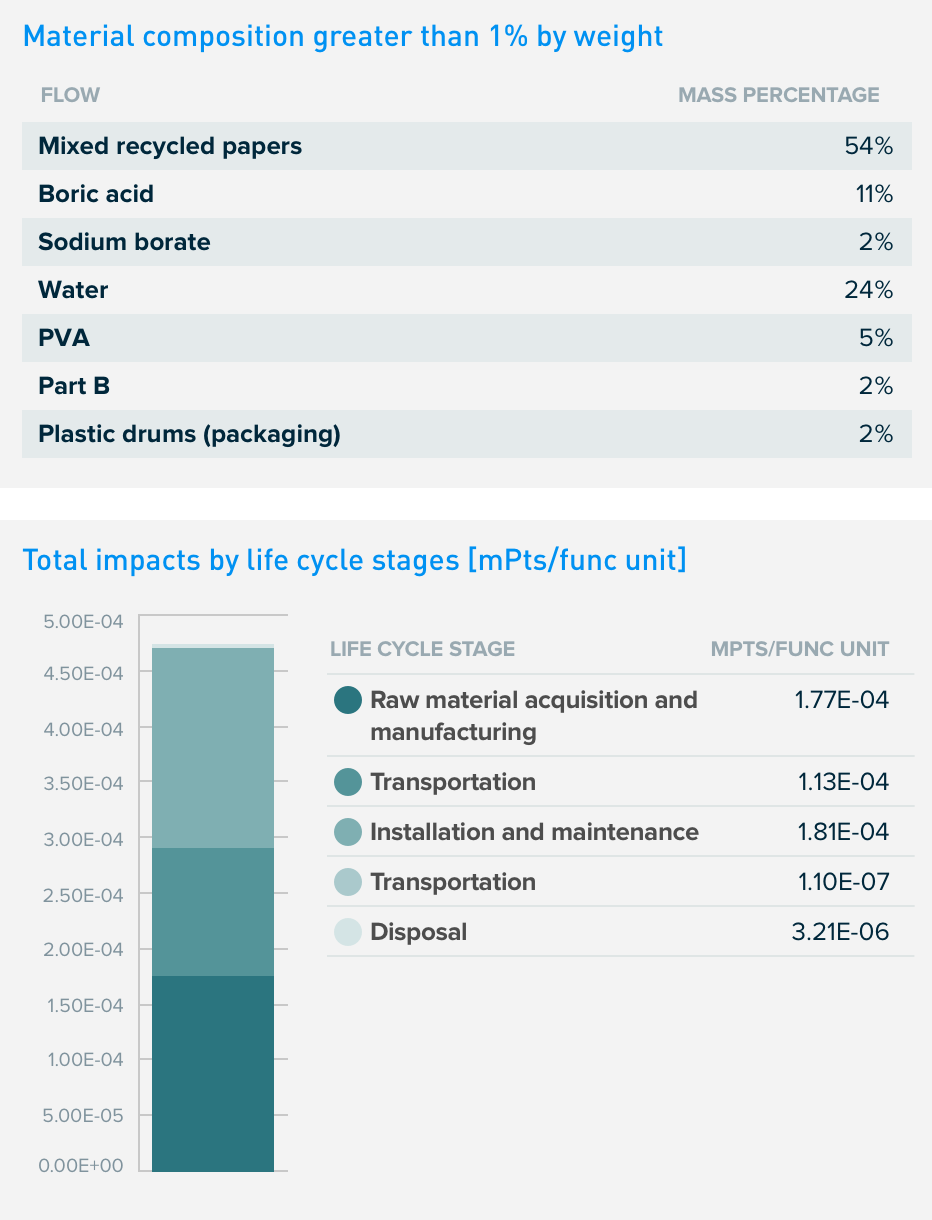

The impact of the raw material acquisition and manufacturing stages are mostly due to the raw material ingredients. The impact of the construction and installation stage are mostly due to electricity used by the installation blowing machine. Some raw material ingredients such as boric acid and ethylene vinyl acetate copolymer (data set used for PVA) have slightly higher impacts than other ingredients. This is because of the high material weights used in manufacturing.

How we're making it greener

ICC has energy, waste and water management policies in place and subscribes to third-party environmental services, which includes inspections, audits, and environmental monitoring.

Water management: Water is utilized only in the manufacturing of the adhesives- which are produced in concentrated form and diluted at the job site. No wastewater is generated from the manufacturing process.

Waste management: ICC practices onsite recycling and has partnered with local business to reduce and reuse packaging materials.

Energy management: Products are manufactured in an electrically driven mill, using a process that requires low embodied energy. Electricity use is monitored and processes to conserve energy have been instilled. These products and the manufacturing of these products does not use ozone depleting substances such as CFC’s or HCFC’s; ozone depletion may occur in the transportation phase or raw material extraction phase.

LCA results

| Life cycle stage | Raw material acquisition and manufacturing | Transportation | Installation and maintenance | Transportation | Disposal/reuse/ recycling |

|

Information modules: Included | Stages C1, C3, and D are being excluded *In the installation and maintenance phase, packaging waste and electricity or gas used by the insulation blowing machines in module A5 are the only contributors to the potential impacts. |

A1 Raw Materials | A4 Transporation/ Delivery | A5 Construction/ Installation | C2 Transportation | C4 Disposal |

| A2 Transportation | B1 Use | ||||

| A3 Manufacturing | B2 Maintenance | ||||

| B3 Repair | |||||

| B4 Replacement | |||||

| B5 Refurbishment | |||||

| B6 Operational energy use | |||||

| B7 Operational water use | |||||

|

|

|

|

|

SM Single Score

Learn about SM Single Score results| Impacts per 75 years of service | 1.77E-04 mPts | 1.13E-04 mPts | 1.81E-04 mPts | 1.10E-07 mPts | 3.21E-06 mPts |

| Materials or processes contributing >20% to total impacts in each life cycle stage | boric acid and ethylene vinyl acetate copolymer used in the production of the insulation. | Truck and trailer, 53ft used to transport product to building site. | Transportation to disposal, energy required for installation with a blowing machine, and disposing of packaging materials. | Transportation to landfill. | Landfilling of product. |

TRACI v2.1 results per functional unit

| Life cycle stage | Raw material acquisition and manufacturing | Transportation | Installation and maintenance | Transportation | Disposal/reuse/ recycling |

Ecological damage

Human health damage

Additional environmental information

| Impact category | Unit | |||||

| Fossil fuel depletion | MJ surplus Mega Joule, lower heating value Fossil fuel depletion is the surplus energy to extract minerals and fossil fuels. |

5.95E+00 | 2.42E+00 | 5.31E+00 | 2.37E-03 | 1.15E-01 |

USEtox percent contribution

| Life cycle stage | Raw material acquisition and manufacturing | Transportation | Installation and maintenance | Transportation | Disposal/reuse/ recycling |

References

LCA Background Report

ICC Insulation Products LCA Background Report (public version), ICC 2020. SimaPro Analyst 8.5.2.0, Ecoinvent 3.1, 2.2 database.

ISO 21930:2017 serves as the core PCR along with EN 15804 and UL Part.

ULE PCR Part A: Life Cycle Assessment Calculation Rules and Report Requirements v3.1.

May 2, 2018. Technical Advisory Panel members reviewed and provided feedback on content written by UL Environment and USGBC. Past and present members of the Technical Advisory Panel are listed in the PCR.

ULE PCR Part B: Building Envelope Thermal Insulation

Version 2.0, April 2018. PCR review conducted by Thomas Gloria, PhD (chair, [email protected]); Andre Desjarlais; and Christoph Koffler, PhD.

ULE General Program Instructions v2.1, April 2017

ISO 14025, “Sustainability in buildings and civil engineering works -- Core rules for environmental product declarations of construction products and services”, ISO21930:2017

Independent external verification of the declaration and data, according to ISO 14025.

Download PDF SM Transparency Report/Material Health Overview, which includes the additional EPD content required by the ASTM Environment PCR.

SM Transparency Reports (TR) are ISO 14025 Type III environmental declarations (EPD) that enable purchasers and users to compare the potential environmental performance of products on a life cycle basis. Environmental declarations from different programs (ISO 14025) may not be comparable. They are designed to present information transparently to make the limitations of comparability more understandable. Limitations of LCA results for the products represent production volumes for the Houston, TX facility only. TRs/EPDs of products that conform to the same PCR and include the same life cycle stages, but are made by different manufacturers, may not sufficiently align to support direct comparisons. They therefore, cannot be used as comparative assertions unless the conditions defined in ISO 14025 Section 6.7.2. ‘Requirements for Comparability’ are satisfied. Comparison of the environmental performance of building envelope thermal insulation using EPD information shall be based on the product’s use and impacts at the building level, and therefore EPDs may not be used for comparability purposes when not considering the building energy use phase as instructed under the PCR. Environmental declarations from different programs based upon differing PCRs may not be comparable. Full conformance with the PCR for building envelope thermal insulation allows EPD comparability only when all stages of a life cycle have been considered, when they comply with all referenced standards, use the same sub-category PCR, and use equivalent scenarios with respect to construction works. Compliance with model building codes does not always ensure compliance with state or local building codes, which may be amended versions of these model codes. Always check with local building code officials to confirm compliancHowever, variations and deviations are possible. Example of variations: Different LCA software and background LCI data sets may lead to different results upstream or downstream of the life cycle stages declared.

SM Transparency Report (EPD)

SM Transparency Report (EPD)