How we make it greener Havelock Wool Batt and Loose-fill Insulation

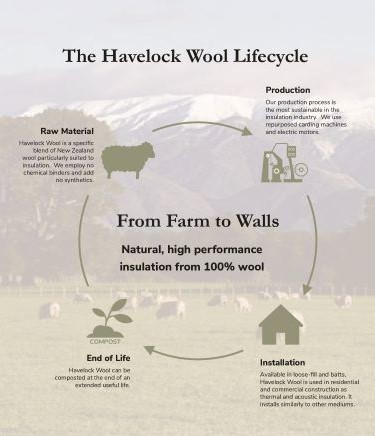

Havelock Wool is a specific blend of New Zealand wool particularly suited for insulation. Our wool is a byproduct of the meat production industry and contains no synthetic mix or bonding agents making our products compostable at the end of extended useful life.

Sheep in New Zealand eat grass fed by rainfall and twice a year they need a haircut. This leads to 5kg or 10kg of wool per year that is available to be cleaned and turned into insulation.

New Zealand is hugely pastoral which limits the amount of vegetable matter (VM) in the wool and therefore allows for scouring (cleaning) to yield a product that carries ~0.1% VM. The US by contrast typically achieves 1.5%. Canada has no scouring capabilities. This minimal amount of VM is important to keep our processing machines in tolerance so we can make a consistent product.

We are approached from around the world with offers to buy wool. We are biased towards New Zealand for quality, consistency and cost though we would like to see that change over time. Though ocean freight is extremely efficient we would like to pick up some raw material in closer proximity to our end-users.

Our production process employs two ingredients – wool and a slight amount of boric acid. Our processing equipment is uniquely simple for many reasons – not least very low power requirements.

Wool is the base fiber for our insulation. We do not include synthetics which typically require high heat and bonding agents to make a consistent finished product. Havelock, conversely, uses repurposed carding machines and a needle punch to make insulation. All of our machines run on electric motors which draw low power.

Our machine maintenance program is consistent and minimally invasive – machines are metal drums with teeth that turn with chains and sprockets or pulleys and belts. Bearings need grease and if a sprocket wears out it is quickly and easily replaced. We produce 6 days / week with almost no disruption.

There is an opportunity to add solar to our building and generate enough power to run our machines during production hours. We are exploring options and intend to add this capability to the equation.

Available in batts and loose-fill, Havelock Wool is used in residential and commercial construction as thermal and acoustic insulation. Havelock wool products install easily – blow-in and batts are installed like other mediums, but no protective clothing is required.

Loose-fill insulation can be installed by hand though pneumatic blowing is recommended. There are various machines fit for installing wool.

Batts are typically cut at 48” and can be applied with friction. A staple may be added at the installer’s discretion. Wire or lightning rods are often used in a ceiling joist or with metal framing.

Our packaging can be made more recyclable. Doing so would noticeably add to cost so we will add this in stages whereby the option becomes available to discerning clientele before a wholesale shift is made.

Wool is a biogenic material. That means materials that are produced directly by the physiologic activities of organisms, either plant or animal. Havelock encourages composting as the optimal end of life method. However, when wool is landfilled, it biodegrades completely after six months.

At Havelock, we will always offer a product that comes from nature providing little impact when it has reached its end of life and returned to the earth.

SM Transparency Report (EPD)

SM Transparency Report (EPD)